Introduction

SSC Shaftless Spiral (Screw) Conveyors offer large volume capacity and the possibility of handling particularly difficult materials. They are designed for handling of urban solid waste, screenings and floating matter, de-watered, thickened, or conditioned sludge, packaged food, creams or pastes, as well as waste from meat, fish, fruit and vegetable processing. The main sectors of application are: waste water treatment, sugarhouse rejects, fish industry, solid waste treatment, fruit and vegetable processing plants, beverage industry, pulp and paper, chemical industry, food industry in general, meat processing plants, abattoirs/slaughterhouses, restaurants, canteens, and catering in general.

High efficiency conveying of difficult materials

Simple design (few components)

Technical Specs

Description

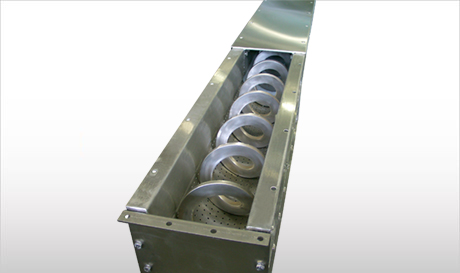

SSC Shaftless Screw or Spiral Conveyor are an alternative concept to traditional shafted screw conveyors. Material is conveyed by an extra heavy-duty shaftless screw that slides on a wear-resistant, low-friction liner inside the conveyor trough housing.

The longitudinally divided U-section troughs are manufactured from carbon or 304 L / 316 L stainless steel, including an appropriate surface treatment. Fabricated parts, except the ultra heavy-duty screw, are of the medium heavy-duty type. The cross section of the lower part of the trough is slightly wider than the side channels to allow for the liner to be inserted in the lower trough part. After complete assembly of the trough the liner is kept in place by the upper trough side channels. At one trough end there is a vertical or flush-type outlet. At the drive end the screw conveyor is equipped with an end plate holding the end bearing assembly with flanged shaft coupling to the spiral. The installed drive unit suits the application.

SSC can be loaded from above into the open trough (standard), or through an inlet spout included in a bolted trough cover (option), or from the side through a special side inlet in the loading zone of the trough (option).

Function

Shaftless screws (spirals) offer a larger volume capacity and the possibility of handling particularly difficult materials like those that tend to become tangled up or those that present highly variable particle size. Material properties, oversize thickness, as well as a special manufacturing process make the spiral highly resistant and extremely durable. Due to the absence of intermediate bearings, obstacle-free material handling is guaranteed. The completely enclosed trough prevents any material leakage. Trough covers with appropriate gaskets enable odour-free operation and form a barrier preventing any atmospheric agents from entering the system. At the same time the conveyor offers maximum access to its inside for inspection and cleaning. Maintenance is reduced to the minimum due to a limited number of components. There is a vast choice of liners depending on specific characteristics of the material handled.

SSC Shaftless Screw (Spiral) Conveyors are designed for handling of difficult heterogeneous materials such as urban solid waste, screenings and floating matter, de-watered, thickened, conditioned sludge, packaged food, creams or pastes, as well as waste from meat, fish, fruit and vegetable processing. The main sectors of application are: waste water treatment, sugarhouse rejects, fish industry, solid waste treatment, fruit and vegetable processing plants, beverage industry, pulp and paper, chemical industry, food industry in general, meat processing plants, abattoirs/slaughterhouses, restaurants, canteens, and catering in general.

Features

- Troughput rates: up to 45 m³/h (26.4 cfm) for sludge; up to 12.9 m³/h (7.6 cfm) for screenings

- Drive power: 0.55 kW (0.75 HP) ~ 9.2 kW (12.34 HP)

- Trough and spiral manufactured from carbon steel or 304L / 316L stainless steel

- UHMWP trough liner

Benefits

- Simple design (few components)

- Small footprint

- Odour-free operation

- High efficiency

- Complete emptying

- High degree of self-cleaning

- Easy to access and clean

- Low maintenance

- Modular components enable easy adaptation to various problems (extremely versatile conveyor for a variety of DIFFICULT materials and a large number of applications)

Options

- Bolted trough cover

- WAM standard inlet spouts

- Inspection and overflow hatches

- Drainage kit

- Trough feet

- Washing nozzles

- Different type power transmissions: direct, coupling transmission, chain transmission, belt transmission

- Different liners available: with wear signalling, bottom bars or plates, white or black colour plastic

- Spiral guiding bar